Our Mission

Nuestra Mission

- A Service Made For People With People In Mind

-Un Servicio Hecho Para La Gente Pensando En La Gente

-Set Appointment

-Establecer Cita

Our Services

What is the Importance Of a Multi - Point Inspection?

Service technicians often recommend that you schedule a multi-point inspection once every 10,000 miles. Not only does it give you a deeper look at your smooth performance during your commutes, but it also offers other benefits:

Increased knowledge: While some drivers may be well-versed in routine oil changes, fluid top-ups, and tire inspections, a multi-point inspection gives you a closer look at what components may be replaced in the future or what you can do to improve your performance.

Increased safety: Staying on top of essential systems and parts like steering, brakes, tires, lights, and windshield wipers brings you peace of mind as multi-point vehicle inspection includes a check of all the critical components.

Lower repair cost: Awareness of your vehicle’s condition also brings savings to your budget. On top of diagnosing existing issues, a deeper inspection can point to the minor repairs that save you from costly replacements in the future.

What Does a Multi-Point Inspection Check?

From your tires to your fluid levels, a multi-point vehicle inspection gives a thorough check of your cars condition, so it’s ready to take on any challenge around town. So, what is in a multi-point inspection?

Fluids: This includes essential fluids like engine oil, transmission fluid, brake fluid, power steering fluid, and coolant.

Filters: When the dirt, dust, debris, and insects get to be too much on the road, a multi-point inspection ensures your vehicle’s oil and air filters aren’t clogged, affecting your performance and efficiency.

Belts & Hoses: These vital parts can become worn over time. A multi-point inspection checks all of the belts and hoses in your car, including the timing belt, drive belt, fuel lines, vacuum lines, and hoses that connect to the radiator, air conditioner, heater, and power steering.

Tires: As another part of your smooth performance on the road, worn tires can be a major safety hazard during rainy conditions and uneven roads.

Battery: A lot of parts work together to bring your seamless performance. Your battery generates the electricity that powers the ignition system, lights, and infotainment system.

Other parts: Other systems included in a multi-point inspection include the engine, transmission, shocks and struts, axle, chassis, exhaust, and steering.

What is a Diagnostic ?

A diagnostic check is a process of checking a vehicle’s systems and components to help identify issues and rectify them. Modern vehicles are equipped with extensive computer networks that can provide information on the engine, brakes, and other related systems.

Conducting vehicle diagnostics

Technicians nowadays use this information to carry out a range of checks to diagnose possible faults with cars before they escalate into potentially expensive problems.

The information is then relayed back to the service provider so they can tell you what will be needed for your car to fix any issues identified during the inspection. This procedure could also include preventative measures as well as industry-standard tests like emissions inspections and brake inspections, where needed.

What Is an Automotive Repair

What comes to mind when your mechanic mentions certain automotive service items that should be performed on your car?

For clarification, the term “automotive service” generally refers to the recommended preventative maintenance items listed in your vehicle's owner's manual that are intended to keep your vehicle in tip-top operating condition.

For example, tires should be rotated and the oil should be changed at certain mileage intervals. However, when your mechanic refers to “automotive repair,” it means that some type of work is needed to fix an unexpected problem, such as replacing shocks, the muffler, or even rebuilding the transmission. So just remember the difference between the words “service” and “repair.”

Most automotive service items are fairly standard across the board in the automotive industry so that any independent auto shop is able to handle any automotive service or repair, whichever is needed. And typically, these independent shops are less expensive than dealerships for the same work. They should also have access to the manufacturer's latest technical service bulletins on how to fix common problems if there are any recalls, or what kind of maintenance is recommended for your particular model of vehicle.

For your future reference, Federal law ensures that automotive service or repairs can be performed at any auto shop without affecting your warranty coverage. So you don't have to go to the dealer where you bought the vehicle unless you just want to in the event your vehicle is included in a recall for a potential problem.

As an added note, if you are purchasing an extended warranty on a new or used vehicle, be sure to check its terms so that you understand who is required to perform certain automotive service or repairs.e,

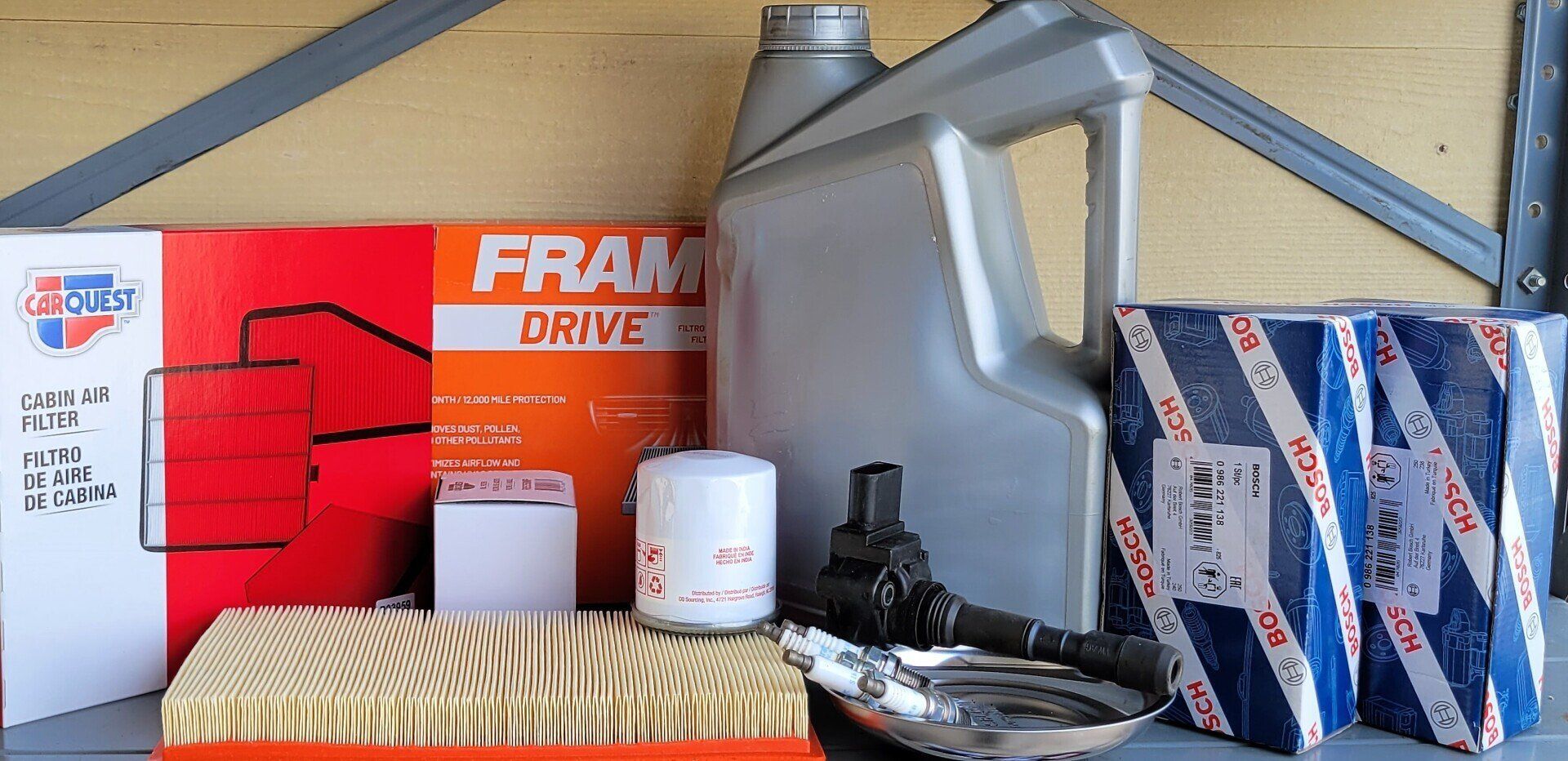

Tune Up / Engine Oil Change / Maintenance

What does a tune-up include

A car tune-up is a suite of preventive maintenance services performed on a vehicle to ensure it continues to perform well. A tune-up typically includes replacing several important wear-and-tear parts, like the air filter, fuel filter, oxygen sensor, positive crankcase ventilation (PCV) valve, and spark plug wires.

How Often Is It Recommended

5,000 to 7,500 miles

It used to be normal to change the oil every 3,000 miles, but with modern lubricants most engines today have recommended oil change intervals of 5,000 to 7,500 miles. Moreover, if your car's engine requires full-synthetic motor oil, it might go as far as 15,000 miles between services!

What Is Proper Maintenance

In our vehicles, the fluids are designed to protect the systems that they run within. One of the main maintenance items on your vehicle is to keep those fluids clean, full, uncontaminated and at the proper protection level. Preventive maintenance is having your vehicle inspected regularly, having the fluids changed regularly before they get dirty, and changing them due to age and mileage. Preventive maintenance would be repairing the cause of any fluids seeping before they are leaking and causing a low-level issue. Preventive maintenance would be checking the fluids regularly for contamination that would prevent them from properly lubricating, cooling, and conditioning the system in the vehicle that it is designed to protect.

There are other systems within our vehicles that need Preventive Maintenance:

Tires:

Rotated regularly and tire pressure checked and kept filled at spec.

Wheel Alignment:

Checking at least yearly for proper wheel alignment and performed if needed.

Spark Plug & Wires Replacement:

Following manufacturer specification for replacement of these items.

PCV Valve, Fuel, Air, and Cabin Air Filter:

Have them inspected and replaced at least once a year.

Throttle Body & Fuel Injectors:

Have them inspected and cleaned at least every 2 years.

Belts, Hoses, Idler Pulleys and Tensioners:

Regularly inspected and replaced as they start to deteriorate or every 60,000 miles (timing belts should be replaced as recommended by manufacturer by age or mileage whichever comes first.)

Brakes & Clutches:

Regularly inspect for leaks, operation and friction material and drum, and rotor trueness and thickness.

Suspension:

Regularly inspect for looseness or leaks and lube all points available.

Preventive maintenance is really the key to the safety, reliability, and longevity of your vehicle. Studies also show preventive maintenance when performed properly also costs about 50% less than just performing repairs when your vehicle breaks.

Brake Services

A brake service typically consists of several key steps to ensure the brake system is functioning properly and safely. Here’s what is generally included in a standard brake service:

Inspection :

Visual Inspection: Checking the condition of the brake pads, rotors, calipers, and other components for wear and damage.

Measurement: Measuring the thickness of the brake pads and rotors to determine if they meet the manufacturer’s specifications.

Fluid Check: Inspecting the brake fluid level and condition. Old or contaminated brake fluid may need to be replaced.

Replacement:

Brake Pads: Replacing worn brake pads with new ones.

Rotors: Resurfacing or replacing rotors if they are worn or damaged beyond acceptable limits.

Calipers: Inspecting calipers for proper operation and replacing them if necessary.

Brake Fluid:

Brake Fluid Flush: Flushing and replacing the old brake fluid to ensure the hydraulic brake system operates effectively. This removes any air, moisture, and contaminants from the system.

Lubrication :

Caliper Pins and Slides: Lubricating the caliper pins and slides to ensure smooth operation and prevent sticking

Adjustments

Parking Brake: Adjusting the parking brake if necessary to ensure it holds the vehicle securely when engaged.

Testing

Brake Function Test: Testing the brakes for proper operation after the service, including checking for any unusual noises, vibrations, or pulling to one side.

Conclusion:

Additional steps might be included depending on the specific vehicle and any unique brake system features it might have. Regular brake services are essential for maintaining vehicle safety and ensuring optimal braking performance.

Suspension Services

Suspension services are essential for maintaining the comfort, handling, and safety of a vehicle. The suspension system absorbs shocks from the road, maintains tire contact, and ensures stability during driving. Here’s what typically comprises suspension services:

Inspection and Diagnosis:

Visual Inspection: Checking for visible signs of wear, damage, or leaks in suspension components such as shocks, struts, springs, and bushings.

Ride Height Measurement: Measuring the vehicle’s ride height to ensure it is within the manufacturer’s specifications.

Road Test: Conducting a road test to identify issues such as excessive bouncing, poor handling, or unusual noises.

Component Replacement:

Shocks and Struts: Replacing worn or damaged shocks and struts that absorb road impacts and maintain ride comfort.

Springs: Replacing coil or leaf springs that may be sagging or broken.

Control Arms: Replacing control arms if the bushings or ball joints are worn or damaged.

Bushings: Replacing worn or damaged bushings that cushion the suspension components and reduce vibrations.

Sway Bars and Links: Replacing worn sway bars and links that help control body roll during cornering.

Ball Joints: Replacing worn ball joints that connect the suspension to the wheels and allow for smooth steering and suspension movement.

Alignment and Balancing:

Wheel Alignment: Adjusting the angles of the wheels to ensure they are perpendicular to the ground and parallel to each other, which is crucial for even tire wear and proper handling.

Tire Balancing: Balancing the tires to prevent vibrations and ensure smooth driving.

Lubrication:

Lubricating Joints: Applying lubrication to suspension joints and components to reduce friction and wear.

Adjustments :

Suspension Adjustments: Making necessary adjustments to the suspension settings to ensure optimal performance and ride quality.

Testing:

Post-Service Test Drive: Conducting a test drive to ensure that the suspension system is functioning correctly and that the vehicle handles properly without any unusual noises or behavior.

Additional Services:

Air Suspension Systems: For vehicles with air suspension, inspecting and repairing or replacing components such as air springs, compressors, and sensors.

Hydraulic Suspension Systems: For vehicles with hydraulic suspension, checking and servicing hydraulic fluid and related components.

Regular suspension services help maintain vehicle stability, improve ride comfort, and ensure safety by keeping the tires in contact with the road. Proper maintenance and timely repairs can prevent more extensive and costly damage to the suspension system and other related components.

Steering System Repairs

Steering system repairs involve diagnosing and fixing issues related to a vehicle's steering mechanism, which is crucial for vehicle control and safety. Here’s what typically comprises steering system repairs:

Inspection and Diagnosis:

Visual Inspection: Checking the steering components for visible damage, wear, or leaks.

Steering Feel: Assessing the steering wheel for unusual play, stiffness, or noises.

Computer Diagnosis: Using diagnostic tools to identify error codes related to electronic steering systems (if applicable)

Component Replacement:

Steering Rack and Pinion: Replacing a damaged or worn steering rack and pinion, which is a common cause of steering problems.

Power Steering Pump: Replacing the power steering pump if it is leaking or not providing sufficient hydraulic pressure.

Tie Rod Ends: Replacing worn or damaged tie rod ends that connect the steering rack to the wheels.

Ball Joints: Replacing worn ball joints that connect the steering knuckles to the control arms.

Bushings: Replacing worn bushings that can affect steering stability and responsiveness.

Fluid Services :

Power Steering Fluid: Flushing and replacing the power steering fluid to ensure the system operates smoothly and to remove any contaminants that could cause damage.

Alignment:

Wheel Alignment: Performing a wheel alignment to ensure the wheels are correctly positioned relative to each other and the road. Proper alignment is crucial for precise steering and even tire wear.

Adjustments and Calibration:

Steering Angle Sensor: Calibrating the steering angle sensor if the vehicle has electronic stability control systems that rely on accurate steering input.

Steering Gearbox: Adjusting the steering gearbox if it has become loose or misaligned.

Testing:

Road Test: Conducting a road test to ensure that the steering system operates correctly and the vehicle tracks straight without pulling to one side.

Steering Response: Checking the responsiveness and feel of the steering to ensure it meets the manufacturer's specifications.

Steering system repairs are essential for maintaining vehicle control, safety, and performance. Regular inspections and timely repairs can prevent more significant issues and ensure the vehicle handles correctly.

Air Conditioning Services

Automotive air conditioning (A/C) systems are vital for ensuring passenger comfort in various weather conditions. Here's an overview of what servicing these systems typically involves:

Inspection and Diagnosis:

Visual Inspection: Checking the condition of A/C components such as the compressor, condenser, evaporator, and refrigerant lines for leaks or damage.

System Performance Test: Measuring the temperature of the air output to determine if the system is cooling effectively.

Pressure Test: Using gauges to check the pressure in the A/C system to identify issues such as low refrigerant levels or blockages.

Component Replacement:

Compressor: Replacing a failed or noisy compressor that is not circulating refrigerant properly.

Condenser: Replacing a damaged or clogged condenser that is not dissipating heat effectively.

Evaporator: Replacing a faulty evaporator that is not cooling the air properly.

Receiver/Drier or Accumulator: Replacing the receiver/drier or accumulator, which removes moisture from the refrigerant.

Expansion Valve or Orifice Tube: Replacing these components if they are clogged or not regulating refrigerant flow properly.

Refrigerant Services:

Refrigerant Recharge: Adding the correct type and amount of refrigerant to the system to ensure proper cooling.

Leak Detection and Repair: Identifying and repairing leaks in the refrigerant system, often using UV dye or electronic leak detectors.

Evacuation and Recharge: Evacuating the system to remove air and moisture, then recharging it with refrigerant.

Cleaning and Maintenance:

Cabin Air Filter: Replacing the cabin air filter to ensure clean air circulation and prevent debris from clogging the system.

Cleaning Evaporator and Condenser Coils: Cleaning these components to improve efficiency and airflow.

Electrical System Check:

Blower Motor and Resistor: Checking and replacing the blower motor and resistor if the air is not blowing properly.

Control Modules and Sensors: Inspecting and replacing faulty control modules or sensors that manage the A/C system operation.

Regular servicing of the A/C systems ensures that they function efficiently, providing comfort and safety for the vehicle occupants. Proper maintenance can prevent costly repairs and extend the lifespan of these systems.

Automotive Heating System

Heating systems are vital for ensuring passenger comfort in various weather conditions. Here's an overview of what servicing these systems typically involves:

Inspection and Diagnosis:

Visual Inspection: Checking the condition of heating components such as the heater core, hoses, and thermostat.

System Performance Test: Measuring the temperature of the air output to determine if the system is heating effectively.

Component Replacement:

Heater Core: Replacing a clogged or leaking heater core that is not providing sufficient heat.

Thermostat: Replacing a faulty thermostat that is not regulating engine temperature properly.

Heater Hoses: Replacing worn or leaking heater hoses that carry coolant to and from the heater core.

Coolant Services:

Coolant Flush and Fill:

Flushing the cooling system to remove old coolant and contaminants, then refilling with fresh coolant.

Leak Detection and Repair: Identifying and repairing leaks in the cooling system.

Blower Motor and Controls:

Blower Motor: Checking and replacing the blower motor if the air is not blowing properly.

Control Valves and Switches: Inspecting and replacing faulty control valves or switches that regulate the flow of hot coolant to the heater core.

Conclusion

Heating systems ensures that they function efficiently, providing comfort and safety for the vehicle occupants. Proper maintenance can prevent costly repairs and extend the lifespan of these systems.

Starting And Charging System

The starting and charging systems in a vehicle are crucial for ensuring reliable engine starts and maintaining the battery’s charge. Here’s an overview of what each system consists of and what servicing typically involves:

Starting System Components:

Battery: Provides the electrical power needed to start the engine.

Starter Motor: Engages with the engine’s flywheel to crank the engine and initiate combustion.

Starter Solenoid: Acts as a relay to transmit electrical current from the battery to the starter motor.

Ignition Switch: Activates the starter system when the key is turned or the start button is pressed.

Flywheel/Flexplate: Engages with the starter motor to turn the engine over.

Starting System Inspection and Diagnosis:

Battery Test: Checking the battery voltage and cold cranking amps (CCA) to ensure it has enough power.

Starter Test: Testing the starter motor for proper operation and checking for unusual noises.

Electrical Connections: Inspecting and cleaning the battery terminals, cables, and starter connections for corrosion or damage.

Ignition Switch: Testing the ignition switch for proper operation.

Starting System Component Replacement :

Battery: Replacing a weak or dead battery.

Starter Motor: Replacing a faulty or worn starter motor.

Starter Solenoid: Replacing a malfunctioning solenoid.

Ignition Switch: Replacing a defective ignition switch.

Charging System Components:

Alternator: Generates electrical power to recharge the battery and power the vehicle’s electrical systems while the engine is running.

Voltage Regulator: Controls the alternator’s output to maintain the correct voltage level.

Battery: Stores electrical energy and provides power when the engine is not running.

Serpentine Belt: Drives the alternator from the engine’s crankshaft.

Charging System Inspection and Diagnosis:

Alternator Output Test: Measuring the voltage and current output of the alternator to ensure it’s charging the battery properly.

Voltage Regulator Test: Testing the regulator to ensure it’s maintaining the correct voltage.

Battery Test: Checking the battery’s state of charge and health.

Belt Inspection: Inspecting the serpentine belt for wear, cracks, or tension issues.

Electrical Connections: Inspecting and cleaning connections between the alternator, battery, and voltage regulator.

Charging System Component Replacement:

Alternator: Replacing a faulty or underperforming alternator.

Voltage Regulator: Replacing a malfunctioning voltage regulator (in some vehicles, this is integrated with the alternator).

Battery: Replacing a battery that is not holding a charge.

Serpentine Belt: Replacing a worn or damaged belt.

Combined Services System Performance Test:

Load Test: Performing a load test to check how the battery and alternator perform under load conditions.

Parasitic Drain Test: Checking for electrical components that may be draining the battery when the vehicle is off.

Combined Services Maintenance:

Cleaning Terminals and Connections: Ensuring all electrical connections are clean and secure.

Tightening Belts and Fasteners: Ensuring all belts are properly tensioned and all fasteners are tight.

Combined Services Diagnostic Codes:

OBD-II Scanner: Using an OBD-II scanner to check for any diagnostic trouble codes related to the starting and charging systems.

Regular maintenance and timely repairs of the starting and charging systems are crucial for reliable vehicle operation, preventing unexpected breakdowns, and ensuring the vehicle’s electrical systems function correctly.

Cooling System Repairs

Cooling system repairs are essential for maintaining the proper operating temperature of a vehicle's engine, preventing overheating, and ensuring efficient engine performance. Here’s an overview of what cooling system repairs typically involve:

Cooling System Components :

Radiator: Dissipates heat from the coolant.

Water Pump: Circulates coolant through the engine and radiator.

Thermostat: Regulates the flow of coolant based on temperature.

Radiator Hoses: Connect the radiator to the engine and allow coolant to flow.

Coolant/Antifreeze: Fluid that absorbs and dissipates heat.

Cooling Fans: Help maintain proper coolant temperature, especially when the vehicle is stationary or moving slowly.

Heater Core: Provides heat to the cabin by using hot coolant from the engine.

Expansion Tank/Reservoir: Stores excess coolant and allows for thermal expansion.

Temperature Sensors: Monitor the temperature of the coolant.

Inspection and Diagnosis:

Visual Inspection: Checking for visible signs of leaks, damage, or corrosion in the cooling system components.

Pressure Test: Applying pressure to the cooling system to identify leaks.

Temperature Check: Using a temperature gauge or infrared thermometer to measure coolant temperatures and ensure the thermostat is functioning properly.

Coolant Condition: Inspecting the coolant for contamination or degradation.

Component Replacement:

Radiator: Replacing a leaking, clogged, or damaged radiator.

Water Pump: Replacing a faulty water pump that is not circulating coolant properly.

Thermostat: Replacing a thermostat that is stuck open or closed, preventing proper coolant flow.

Radiator Hoses: Replacing cracked, swollen, or leaking hoses.

Heater Core: Replacing a leaking or clogged heater core.

Cooling Fans: Replacing non-functional cooling fans or their associated relays and switches.

Coolant Services:

Coolant Flush: Flushing the old coolant and contaminants from the system and refilling with fresh coolant.

Leak Repair: Identifying and repairing leaks in the radiator, hoses, water pump, or other components.

Bleeding Air: Removing air pockets from the cooling system to ensure proper coolant circulation.

Maintenance:

Cleaning Radiator Fins: Cleaning debris from the radiator fins to improve airflow and cooling efficiency.

Inspecting and Replacing Cap: Ensuring the radiator or expansion tank cap maintains proper pressure in the cooling system.

Testing:

System Performance Test: Running the engine and monitoring the cooling system's performance, including checking for leaks and ensuring proper temperature regulation.

Road Test: Conducting a road test to confirm the cooling system functions correctly under normal driving conditions.

Additional Considerations:

Thermal Sensors and Switches: Replacing or repairing faulty temperature sensors and fan switches that control the cooling fans.

Head Gasket Check: Checking for signs of a blown head gasket, which can cause coolant loss and engine overheating.

Coolant Type: Ensuring the correct type and mixture of coolant is used, as specified by the vehicle manufacturer.

Regular maintenance and timely repairs of the cooling system are crucial for preventing engine overheating, which can cause severe engine damage. Properly functioning cooling systems ensure efficient engine performance and longevity.

Emission System Repairs

Emission system repairs are essential for ensuring that a vehicle meets environmental regulations and operates efficiently. The emission system controls and reduces the pollutants produced by the engine. Here’s an overview of what emission system repairs typically involve:

Emission System Components:

Catalytic Converter: Converts harmful gases like carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) into less harmful emissions.

Oxygen Sensors (O2 Sensors): Monitor the level of oxygen in the exhaust gases and provide feedback to the engine control unit (ECU) to adjust the air-fuel mixture.

Exhaust Gas Recirculation (EGR) Valve: Recirculates a portion of the exhaust gases back into the engine cylinders to reduce NOx emissions.

Evaporative Emission Control (EVAP) System: Prevents fuel vapors from escaping into the atmosphere and routes them to the engine to be burned.

Air Injection System: Injects fresh air into the exhaust stream to help burn off excess hydrocarbons.

PCV Valve (Positive Crankcase Ventilation Valve): Redirects blow-by gases from the crankcase back into the intake manifold to be burned in the combustion process.

Muffler and Exhaust Pipes: Reduce noise and direct exhaust gases safely out of the vehicle.

Fuel Cap: Prevents fuel vapor from escaping the fuel tank.

Inspection and Diagnosis:

Visual Inspection: Checking for visible signs of damage, leaks, or corrosion in the exhaust and emission components.

OBD-II Scanner: Using an On-Board Diagnostics scanner to read diagnostic trouble codes (DTCs) and identify issues with the emission system.

Smoke Test: Using a smoke machine to detect leaks in the EVAP system.

Emissions Test: Performing a tailpipe emissions test to measure the levels of pollutants and ensure they meet regulatory standards.

Component Replacement:

Catalytic Converter: Replacing a clogged, damaged, or inefficient catalytic converter.

Oxygen Sensors: Replacing faulty oxygen sensors that provide incorrect data to the ECU.

EGR Valve: Cleaning or replacing a malfunctioning EGR valve.

EVAP System Components: Replacing damaged or leaking components such as the charcoal canister, purge valve, or vent valve.

PCV Valve: Replacing a clogged or malfunctioning PCV valve.

Air Injection System Components: Replacing faulty air pumps, valves, or air hoses.

Cleaning and Maintenance:

Throttle Body and Intake Manifold: Cleaning carbon deposits from the throttle body and intake manifold to ensure proper air flow and sensor function.

EGR System Cleaning: Removing carbon buildup from the EGR valve and passages.

Repairing Leaks:

Exhaust Leaks: Repairing or replacing leaking exhaust pipes, mufflers, or gaskets.

EVAP System Leaks: Sealing or replacing components that are allowing fuel vapors to escape.

Testing and Verification:

Functional Test: Running the engine and monitoring the emission system’s performance to ensure all components are functioning correctly.

Emissions Retest: Conducting a follow-up emissions test to confirm that the repairs have resolved the issues and the vehicle meets regulatory standards.

Software Updates:

ECU Updates: Updating the engine control unit software if there are updates available that improve emissions performance or address known issues.

Additional Considerations:

Fuel Quality: Ensuring the use of the correct fuel type and quality to prevent damage to emission components.

Regular Maintenance: Regularly servicing the vehicle and replacing worn components to prevent emission-related issues.

Legal Compliance: Ensuring all repairs comply with local and federal emission regulations and standards.

Proper maintenance and timely repairs of the emission system are crucial for reducing environmental impact, passing emissions tests, and ensuring the vehicle operates efficiently and reliably.

Engine Service

Engine service encompasses a wide range of maintenance and repair tasks designed to keep an engine running smoothly, efficiently, and reliably. Regular engine service is crucial for prolonging the life of the engine and ensuring optimal performance. Here’s what typically consists of engine service:

Routine Maintenance:

Oil Change:

Drain and Replace Oil: Draining old engine oil and replacing it with fresh oil to lubricate engine components and reduce friction.

Oil Filter Replacement: Changing the oil filter to ensure it can effectively filter out contaminants.

Air Filter Replacement:

Replacing the Air Filter: Installing a new air filter to ensure the engine receives clean air for combustion.

Fuel Filter Replacement:

Replacing the Fuel Filter: Ensuring that clean fuel reaches the engine by replacing the fuel filter.

Spark Plugs:

Replacing Spark Plugs: Changing old or worn spark plugs to ensure proper ignition of the fuel-air mixture.

Fluids Check and Top-Up:

Coolant: Checking the coolant level and topping it up or replacing it to prevent engine overheating.

Brake Fluid: Ensuring the brake fluid is at the correct level and replacing it if necessary

.

Transmission Fluid: Checking and replacing the transmission fluid to ensure smooth gear shifts.

Power Steering Fluid: Ensuring the power steering fluid is at the correct level for optimal steering performance.

Intermediate Maintenance:

Timing Belt/Chain:

Replacement: Replacing the timing belt or chain at the manufacturer-recommended intervals to prevent engine damage.

Drive Belts:

Inspection and Replacement: Checking for wear and replacing serpentine belts or other drive belts that power engine accessories.

Valve Adjustment:

Adjusting Valves: Ensuring the engine’s valves open and close at the correct times by adjusting them as needed.

Throttle Body Cleaning:

Cleaning the Throttle Body: Removing carbon deposits to ensure smooth throttle response.

PCV Valve:

Replacement: Replacing the Positive Crankcase Ventilation (PCV) valve to maintain proper engine ventilation and prevent oil leaks.

Advanced Maintenance and Repairs:

Compression Test:

Performing a Compression Test: Checking the engine’s cylinders for proper compression, which is essential for engine performance and efficiency.

Head Gasket Replacement:

Replacing the Head Gasket: Fixing a blown head gasket that can cause coolant leaks and engine overheating.

Injector Cleaning/Replacement:

Cleaning or Replacing Fuel Injectors: Ensuring the fuel injectors deliver the correct amount of fuel to the engine.

Engine Mounts:

Inspection and Replacement: Checking and replacing worn engine mounts to reduce vibrations and maintain proper engine alignment.

Radiator and Cooling System:

Inspection and Repair: Checking the radiator, hoses, and water pump for leaks or damage and replacing as necessary.

Coolant Flush: Flushing the cooling system to remove old coolant and contaminants, then refilling with fresh coolant.

Exhaust System:

Inspection and Repair: Checking for leaks, corrosion, or damage in the exhaust system and repairing or replacing components as needed.

Diagnostics:

Check Engine Light:

OBD-II Scan: Using an On-Board Diagnostics scanner to read trouble codes and diagnose issues indicated by the check engine light.

Engine Noise and Vibration Analysis:

Identifying and Addressing Issues: Diagnosing unusual engine noises or vibrations and addressing underlying problems.

Performance Testing:

Dyno Testing: Measuring engine performance on a dynamometer to ensure it meets expected power and efficiency standards.

Additional Considerations:

Software Updates: Updating the engine control unit (ECU) software if necessary to improve performance and efficiency.

Regular Inspections: Conducting regular visual inspections and listening for unusual sounds to catch potential issues early.

Regular engine service helps maintain the engine’s reliability, performance, and efficiency, preventing costly repairs and extending the vehicle's lifespan. Following the manufacturer’s recommended maintenance schedule is crucial for keeping the engine in top condition.

Transmission Services

Transmission service typically consists of several key maintenance tasks aimed at ensuring the smooth and efficient operation of a vehicle's transmission system. Here's a detailed breakdown of what transmission service usually includes:

Fluid Change or Flush

Fluid Change: Draining the old transmission fluid and replacing it with new fluid. This helps remove contaminants and debris.

Fluid Flush: A more comprehensive process where all the old fluid is removed, often using a machine, and replaced with new fluid. This ensures a thorough cleaning of the transmission system.

Filter Replacement

Replacing the transmission filter (if applicable) to ensure that any contaminants are effectively removed from the fluid before it circulates through the transmission.

Gasket and Pan Inspection

Inspecting and replacing the transmission pan gasket and inspecting the pan itself for any signs of wear, damage, or leaks.

Checking and Adjusting Fluid Levels

Ensuring the transmission fluid is at the correct level and topped up if necessary. Proper fluid level is crucial for transmission performance and longevity

Inspecting Transmission Components

Inspecting key transmission components such as the clutch (in manual transmissions), torque converter, solenoids, and other internal parts for wear or damage.

Computer Diagnostics

Using diagnostic tools to check for any error codes or issues reported by the vehicle's onboard computer system related to the transmission.

Adjustments and Fine-Tuning

Making necessary adjustments to the transmission’s bands and controls to ensure optimal performance and shifting.

Road Test

Performing a road test to ensure the transmission is functioning properly and to verify that any issues have been resolved.

Seal and Gasket Replacement (if needed)

Replacing any worn or damaged seals and gaskets to prevent leaks and ensure proper pressure within the transmission system.

Optional Services:

Transmission Cooler Service: Inspecting and servicing the transmission cooler to ensure it is effectively cooling the transmission fluid.

Additives: Adding transmission fluid additives designed to improve performance or address specific issues (though opinions on their effectiveness vary).

Regular transmission service helps prevent major transmission failures and extends the life of the vehicle’s transmission. It is typically recommended to follow the vehicle manufacturer's service intervals and guidelines for transmission maintenance.

Transfer Case Services

Transfer case service is essential for maintaining the proper function of a vehicle's drivetrain, especially in four-wheel drive (4WD) and all-wheel drive (AWD) vehicles. The transfer case is responsible for distributing power from the transmission to the front and rear axles. Here’s what a typical transfer case service consists of:

Fluid Change

Draining Old Fluid: Removing the old transfer case fluid, which can become contaminated over time with metal shavings and debris.

Refilling with New Fluid: Refilling the transfer case with the correct type and amount of fluid specified by the vehicle manufacturer. This ensures proper lubrication and operation of the internal components.

Inspection of Components

Visual Inspection: Checking the transfer case and surrounding components for signs of leaks, damage, or excessive wear.

Seals and Gaskets: Inspecting and replacing any worn or damaged seals and gaskets to prevent fluid leaks.

Checking and Adjusting Fluid Levels

Ensuring the fluid level is correct, which is crucial for the transfer case to function properly.

Inspecting Mounting and Connections

Mounts and Bolts: Checking that the transfer case is securely mounted and that all bolts and connections are tight.

Drive Shafts and U-Joints: Inspecting the drive shafts and universal joints (U-joints) for wear or damage, as these are critical for the transfer case’s operation.

Checking for Unusual Noises

Operational Noises: Listening for any unusual noises while the vehicle is in motion, which could indicate issues within the transfer case.

Computer Diagnostics (if applicable)

Error Codes: Using diagnostic tools to check for any fault codes related to the transfer case system, especially in modern vehicles with electronic control systems.

Road Test

Performance Verification: Conducting a road test to ensure the transfer case is functioning correctly, particularly when engaging and disengaging 4WD or AWD modes.

Replacing or Repairing Components (if needed)

Internal Parts: If the inspection reveals significant wear or damage to internal parts such as gears, bearings, or chains, these components may need to be replaced or repaired.

Optional Services:

Transfer Case Flush: In some cases, a more thorough flushing of the transfer case may be performed to remove all old fluid and contaminants.

Additives: Adding specific additives designed to enhance the performance of the transfer case fluid (though this is often at the discretion of the service provider and based on manufacturer recommendations).

Regular transfer case service is crucial to ensure the longevity and reliability of your vehicle’s drivetrain. The recommended service interval can vary depending on the vehicle make and model, so it's important to follow the guidelines provided in the vehicle's owner manual.

Differential Services

Differential service is an essential maintenance procedure for ensuring the smooth operation and longevity of a vehicle's differential. The differential is responsible for distributing power to the wheels while allowing them to rotate at different speeds, which is crucial for smooth turning. Here’s what a typical differential service consists of:

Fluid Change :

• Draining Old Fluid: Removing the old differential fluid, which can accumulate metal particles and contaminants over time.

• Refilling with New Fluid: Adding the correct type and amount of new differential fluid as specified by the vehicle manufacturer. Proper lubrication is crucial for the gears and bearings within the differential.

Inspection of Components

• Visual Inspection: Checking the differential housing and components for signs of wear, damage, or leaks.

• Seals and Gaskets: Inspecting and replacing any worn or damaged seals and gaskets to prevent fluid leaks and ensure proper sealing.

Checking and Adjusting Fluid Levels

• Ensuring the fluid level is correct, which is essential for the differential’s proper operation and longevity

Inspecting Differential Gears and Bearings

• Gears: Examining the condition of the gears for any signs of wear, pitting, or damage.

• Bearings: Checking the bearings for smooth operation and any signs of wear or damage.

Checking for Unusual Noises

• Operational Noises: Listening for any unusual noises coming from the differential while the vehicle is in motion, which could indicate issues such as worn gears or bearings

Axle Inspection

• Axle Shafts: Inspecting the axle shafts connected to the differential for any signs of wear or damage.

• U-Joints and CV Joints: Checking the universal joints (U-joints) and constant velocity joints (CV joints) for wear, as they are critical for the differential’s operation.

Cleaning the Differential Housing

• Debris Removal: Cleaning out any debris or metal shavings from the differential housing to prevent contamination of the new fluid.

Road Test

• Performance Verification: Conducting a road test to ensure the differential is functioning correctly and to verify that any issues have been resolved.

Optional Services:

• Differential Cover Gasket Replacement: Replacing the differential cover gasket if it shows signs of wear or leakage.

• Differential Flush: In some cases, a more thorough flushing of the differential may be performed to remove all old fluid and contaminants.

• Additives: Adding specific additives designed to enhance the performance of the differential fluid, though this depends on the manufacturer’s recommendations and the service provider’s discretion.

Regular differential service helps prevent major differential failures and extends the life of the differential components. The recommended service interval can vary based on the vehicle make and model, driving conditions, and manufacturer guidelines, so it’s important to refer to the vehicle’s owner manual for specific recommendations

Interior Electrical Components

Automotive interior electrical components include various systems and devices that enhance functionality, comfort, and safety within the vehicle's cabin. Here is a detailed list of these components:

Infotainment System:

Touchscreen Display: For controlling audio, navigation, and other vehicle settings.

Audio System: Includes radio, CD player, speakers, and amplifiers.

Navigation System: GPS and map display for route guidance.

Connectivity: Bluetooth, USB ports, and auxiliary inputs for connecting external devices.

Climate Control System:

HVAC Controls: Electronic controls for heating, ventilation, and air conditioning.

Blower Motor: Electrically powered fan for circulating air.

Sensors: Temperature and humidity sensors for automatic climate adjustments.

Lighting

Interior Lights: Dome lights, reading lights, and ambient lighting.

Instrument Panel Illumination: Backlighting for gauges and displays.

Footwell and Console Lighting: For enhanced visibility inside the cabin.

Power Accessories

Power Windows: Electrically operated windows with controls on the doors or center console.

Power Mirrors: Electrically adjustable and often heated side mirrors.

Power Seats: Electrically adjustable seats with memory settings.

Sunroof/Moonroof Controls: Electronic operation of sunroofs or moonroofs.

Steering Wheel Controls:

Multifunction Buttons: Controls for audio, cruise control, phone, and other functions.

Heated Steering Wheel: Electrically heated steering wheel for added comfort in cold weather.

Instrument Cluster:

Digital Displays: Speedometer, tachometer, fuel gauge, and other indicators.

Warning Lights: Alerts for various vehicle systems (e.g., check engine, low fuel).

Safety Systems:

Airbag System: Electrically controlled deployment of airbags.

Seat Belt Pre-tensioners: Electrically activated mechanisms that tighten seat belts in a crash.

Occupant Detection System: Sensors to detect passenger presence and adjust airbag deployment.

Driver Assistance Systems:

Cruise Control: Electronic control of vehicle speed.

Lane Departure Warning: Alerts driver if the vehicle drifts out of its lane.

Blind Spot Monitoring: Sensors that detect vehicles in the driver's blind spots.

Communication Systems:

Bluetooth Connectivity: Wireless communication for phones and other devices.

Hands-Free Calling: Integration with the infotainment system for making and receiving calls.

Voice Recognition: Allows control of various functions using voice commands.

Charging Ports:

USB Ports: For charging devices and data transfer.

12V Power Outlets: Standard car power outlets for various accessories.

Seats

Heated and Ventilated Seats: Electrically controlled heating and cooling for seats.

Massaging Seats: Electrically operated massage functions.

Head-Up Display (HUD):

Projection Display: Projects important information (e.g., speed, navigation) onto the windshield.

These electrical components are interconnected through the vehicle's wiring harness and controlled by various electronic control units (ECUs) to ensure seamless operation and enhance the overall driving experience.

Tires

Tire service consists of a range of activities and maintenance tasks aimed at ensuring that a vehicle's tires are in optimal condition for safe and efficient driving. Here are the main components of tire service:

Tire Inspection

Visual Inspection: Checking for visible damage such as cuts, cracks, punctures, and bulges.

Tread Depth Measurement: Using a tread depth gauge to measure the depth of the tire tread to ensure it meets legal and safety standards.

Pressure Check: Measuring tire pressure and ensuring it meets the manufacturer’s recommended levels.

Tire Rotation

Rotating Tires: Moving tires from one position on the vehicle to another (e.g., front to rear, left to right) to promote even tread wear and extend tire life.

Tire Balancing

Balancing Tires: Adding small weights to the wheel to ensure that the tire weight is evenly distributed around the axle, reducing vibration and preventing uneven wear.

Wheel Alignment

Adjusting Alignment: Correcting the angles of the wheels so they are set to the car manufacturer’s specifications, ensuring the vehicle drives straight and tires wear evenly.

Tire Repair

Puncture Repair: Fixing small punctures using patches or plugs.

Valve Stem Replacement: Replacing damaged or leaking valve stems.

Tire Replacement

Removing Old Tires: Taking off worn-out or damaged tires.

Installing New Tires: Mounting new tires onto the wheels and ensuring they are properly seated and balanced.

Tire Pressure Monitoring System (TPMS) Maintenance

Sensor Check and Replacement: Inspecting and, if necessary, replacing TPMS sensors that monitor tire pressure.

TPMS Recalibration: Ensuring the TPMS is properly calibrated to provide accurate pressure readings.

Description Title

Regular tire service is crucial for maintaining vehicle safety, improving fuel efficiency, and extending the lifespan of the tires.

Synchrony Financial

We know repairs can sometimes be expensive and unexpected, so we are proud to offer financing through Synchrony Car Care.

Synchrony Financial is currently offering 12-month 0% interest promotional financing on purchases of $750 or more.

Snap Finance

Evolution Auto Care has invited you to apply with Snap Finance. Use this link to accept your invitation

Contact us

We're here to help! Send any questions you have over to us. We look forward to hearing from you.

Contact Us

We will get back to you as soon as possible

Please try again later

"A service for the people with people in mind"

Come Visit Us

Hours Of Operation

Monday - Friday

8 AM To 6:30 Pm